Your cart is empty

Essential oil distillation machine with 1100 liter stainless steel vessel

Stainless steel distilling machine with boiler and distillation tanks for professionals.

Components.

Low pressure steam production stainless steel boiler.

Image of oven opening for wood-fired version with ashtray. Wood version.

Diesel version boiler.

85,0 cm in diameter x 125,0 cm in body height.

2 meters of stainless steel chimney included. Automation elements for pressure control and automatic water loading. (The boiler produces steam at low pressure 0.4 bar.)

Automated system for filling boilers at the indicated level, with a Pyrex display

Brass safety valve.

Pressure gauge.

Steam purge valve.

Steam outlet with DN32 connection

Boiler with water softener with a nominal flow rate of 450 l/h

With 1" automatic Clack valve,

7" FRP column, 15l DOWEX cathode resin and a 100l brine tank.

Boiler with stainless steel ash tank with feed tube and connection for working with wood. (consult us for gas burner)

Distiller tank in AISI 304 stainless steel.

Diameter 94,5 x 150,0 cm height of the body for placing plants.

Special and fast closure.

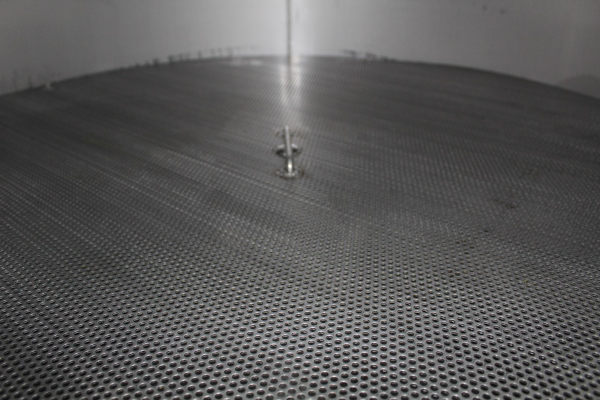

Steam inlet with DN25 connection, distribution with conical steam diffuser, at the bottom of the bowl for a better distribution of steam.

Perforated stainless steel grid to support plants. The grate is raised with chains to facilitate unloading.

Condensed steam drain outlet.

Exit of swan neck type distillates.

Cooling cube with stainless steel coil.

200 liter capacity, with lid.

Diameter 600mm x 720mm height.

Distillate refrigeration helical coil

Made of AISI304 Ø33.7mm stainless steel

1" thread for water inlet

1" thread for water outlet

Drain outlet at the bottom.

Oil and water separator in stainless steel.

Diameter. 30cm x 40cm high.

Automatic product separation.

Advantages of the vieirinox 1100 distilling machine

- The distillation plant in stainless steel is designed to be efficient.

- Low fuel consumption. (gas, diesel or wood)

- Safe and reduced work space.

- Ease of work. It is loaded and unloaded from above with a grid with stainless steel chains.

- production is continuous, automatic water refill.

- The plant can be automated.

- Thanks to its modular design, it can be expanded in the future by adding distillation tanks. You can add another glass. The boiler can power two distillation tanks working at the same time. It is also possible to add distillation tanks on standby so that it is continuously working.

- Long duration. Being made with the highest quality materials and good thicknesses of stainless steel.

The plant is shipped ready to plug and play. It is necessary for the client to install a water purification system and the electrical outlet.

If you are interested, send us an email and your contact information and needs to:

info@cobrelis.com